Diagramma Fluxus

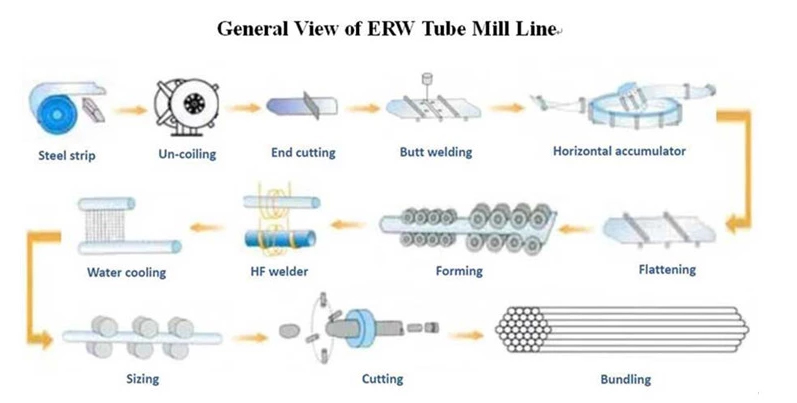

{Laminae ferreae} →→Evolvetor bicipitis→→ Tondetrix Capitis Striati et Statio Soldatoris TIG ad Coniunctionem →→Accumulator Spiralis Horizontalis→→Formans M/C (Unitas impulsoria principalis ①)+ Unitas Ingressus Planationis + Zona Disruptionis + Zona Transitus Pinnarum + Unitas Ductoris Suturae + Systema Soldaturae Inductionis Altae Frequentiae + Unitas Cylindri Soldaturae Compressi + Unitas Scrutationis Externae + Systema Sarcinationis Pulveris Zinci pro Sutura Soldata (ad libitum) + Basis Ferri Horizontalis) +Sectio refrigerationis aquae emulsionis+Dimensionatio M/C (Pars impulsoria principalis ② + Zona dimensionationis + Unitas probationis celeritatis + Instrumentum ad lineas explanandas Turcicas + Structura extractionis verticalis)→→Serra volans frigida NC sub imperio computatrali→→Tabula excursus →→{Sectio congeriendi et convasandi (ad libitum)}

Introductio producti

1. Plus quam viginti annos experientiae professionalis in fabricatione accumulata, SHANGHAI COREWIRE INDUSTRY CO., LTD. in supplendo machinae molendinae tubularis TM-12~273 ERW specializata, qualitatem emendare et investigationem technologicam conari conatur.

2. Interea, centrum investigationis et progressionis molam tubularem ERW cum designo altae firmitatis, selectione materiarum, machinatione praecisa, operatione stabili, et conservatione energiae exhibuit.

Applicatio

Producta sunt praecipue tubi et fistulae adhibitae in petroleo, petrochemica, constructione, navium constructione, rebus militaribus, energia electrica, fodinis, carbone, machinarum fabricatione.

Linea Productionis Personalisata

Hoc TM-32 Mola Tuborum et Fistularum ERW, completa cum evolvente et tondente capite striato et statione ad ferramentum fundi et mola formatrice et mola mensuratrice et serra volante frigida et mensa conveyor et machina congerendi et implendi. Designatio optimizata, selectio materiae summae qualitatis, et processus curationis caloris strictus praestant magnam praecisionem, resistentiam attritioni, et longam vitam cylindri.

Specificatio ERW

| Modellum | Diametros exteriores tubi | Crassitudo muri | Quadratum/Rectangulum | Crassitudo muri | Celeritas | Motor principalis | HFWelder |

| TM-12 | φ4~φ12 | 0.2~0.5 | // | // | XXX~CXX | 15 | centum |

| TM-16 | φ6~φ16 | 0.2~0.8 | // | // | XXX~CXX | XXII | centum |

| TM-20 | φ7~φ20 | 0.2~1.0 | // | // | XXX~CXX | 30 | centum |

| TM-25 | φ9~φ25.4 | 0.25~1.2 | // | // | XXX~CXX | 37 (vel 22 * 2) | centum |

| TM-32 | φ10~φ32 | 0.25~1.5 | 8*8~25.4*25.4 | 0.25~1.2 | XXX~CXX | 45 (vel 30 * 2) | centum |

| TM-32z | 0.5~2.0 | 0.5~1.5 | Triginta~C | 55 (vel 37*2) | centum | ||

| TM-40 | φ12.7~φ40 | 0.3~1.8 | 10*10~31.8*31.8 | 0.3~1.5 | XXX~CX | 75 | CL |

| TM-40z | 0.6~2.0 | 0.6~1.5 | Triginta~C | 45*2 | CL | ||

| TM-50q | φ16~φ50.8 | 0.4~1.5 | 12.7*12.7~40*40 | 0.4~1.2 | XXX~CX | 90 | CL |

| TM-50 | 0.5~2.0 | 0.5~1.5 | XXX~XC | 45*2 (vel 110) | ducenti | ||

| TM-50z | 0.7~2.5 | 0.7~2.0 | XXX~LXXX | 55*2 | ducenti | ||

| TM-63q | φ19.05~φ63.5 | 0.6~2.0 | 15*15~50*50 | 0.6~1.5 | XXX~XC | 132 (vel 55*2) | CL |

| TM-63 | 0.7~3.0 | 0.7~2.5 | XXX~LXXX | 75*2 (vel 132) | ducenti | ||

| TM-63z | 0.8~3.5 | 0.8~3.0 | XX~LXX | 90*2 | ducenti | ||

| TM-76q | φ25.4~φ76.2 | 0.8~2.5 | 20*20~60*60 | 0.8~2.0 | XXX~XC | CLX (vel LXXV*II) | ducenti |

| TM-76 | 0.8~3.5 | 0.8~3.0 | XXX~LXXX | 90*2 | 250 | ||

| TM-76z | 0.8~4.0 | 0.8~3.5 | XX~LXX | trecenti | |||

| TM-90q | φ30~φ90 | 0.8~3.0 | 25*25~70*70 | 0.8~2.5 | XXX~XC | CLXXX (vel XC*II) | 250 |

| TM-90 | 0.8~3.5 | 0.8~3.0 | XXX~LXXX | 110*2 | 250 | ||

| TM-90z | 1.0~4.0 | 1.0~3.5 | XX~LXX | trecenti |

| Modellum | Diametros exteriores tubi | Crassitudo muri | Quadratum/Rectangulum | Crassitudo muri | Celeritas | Motor principalis | HFWelder |

| TM-100q | φ31.8~φ101.6 | 1.0~3.0 | 25*25~80*80 | 1.0~2.5 | XXX~XC | 200 (vel 110*2) | 250 |

| TM-100 | 1.0~3.75 | 1.0~3.25 | XXX~LXXX | 110*2 | trecenti | ||

| TM-100z | 1.0~4.25 | 1.0~3.5 | XX~LXX | 132*2 | trecenti | ||

| TM-114q | φ35~φ114.3 | 1.0~3.0 | 30*30~90*90 | 1.0~2.5 | XX~LXXX | 110*2 | trecenti |

| TM-114 | 1.2~4.5 | 1.2~4.0 | XX~LXX | 132*2 | 350 | ||

| TM-114z | φ40~φ114.3 | 1.2~5.0 | 1.2~4.5 | XV~LX | 350 | ||

| TM-127q | φ40~φ127 | 1.2~3.5 | 40*40~100*100 | 1.2~3.0 | XX~LXX | 132*2 | 350 |

| TM-127 | 1.5~5.0 | 1.5~4.5 | XV~LX | 160*2 | quadringenti | ||

| TM-127z | φ50~φ127 | 1.5~5.5 | 1.5~5.0 | 10~45 | 160*2 | quadringenti | |

| TM-140q | φ50~φ141.3 | 1.2~4.0 | 50*50~110*100 | 1.2~3.5 | XV~LX | 160*2 | quadringenti |

| TM-140 | 1.5~5.5 | 1.5~5.0 | 10~50 | CLXXX*II | quadringenti | ||

| TM-140z | φ60~φ141.3 | 2.0~6.0 | 2.0~5.5 | 10~40 | CLXXX*II | quingenti | |

| TM-168q | φ60~φ168.3 | 1.5~5.0 | 60*60~130*130 | 1.5~4.5 | 10~50 | CLXXX*II | quadringenti |

| TM-168 | 2.0~6.0 | 2.0~5.5 | 10~50 | 200*2 | quingenti | ||

| TM-168z | φ76.2~φ168.3 | 2.5~8.0 | 2.5~7.0 | 10~40 | 200 + 132 * 2 | DC | |

| TM-219q | φ89.1~φ219.1 | 2.0~6.0 | 70*70~160*160 | 2.0~5.5 | 10~50 | 110*2+110*2 | quingenti |

| TM-219 | 3.0~8.0 | 3.0~7.0 | 10~40 | 132*2+132*2 | DC | ||

| TM-219z | 4.0~10.0 | 4.0~9.0 | 10~40 | 132*2+160*2 | DCCC | ||

| TM-273 | φ114.3~φ273 | 4.0~10.0 | 90*90~200*200 | 4.0~9.0 | 10~40 | 160*2+160*2 | DCCC |

| TM-273z | 4.5~12.0 | 120*60~260*130 | 4.5~11.0 | 10~35 | CLXXX*IV | DCCC |

Ostentatio Applicationis

Applicatio:

Producta sunt praecipue tubi et fistulae adhibitae in petroleo, petrochemica, constructione, navium constructione, autocinetorum fabricatione, energia electrica, fodinis, carbone, machinarum fabricatione.